Tractor Soil Stabilizer for Improving Roads

The Soil Stabilizer is the ultimate solution for high-performance road and ground stabilization, engineered for tractors with 300–500 HP.

Product Overview

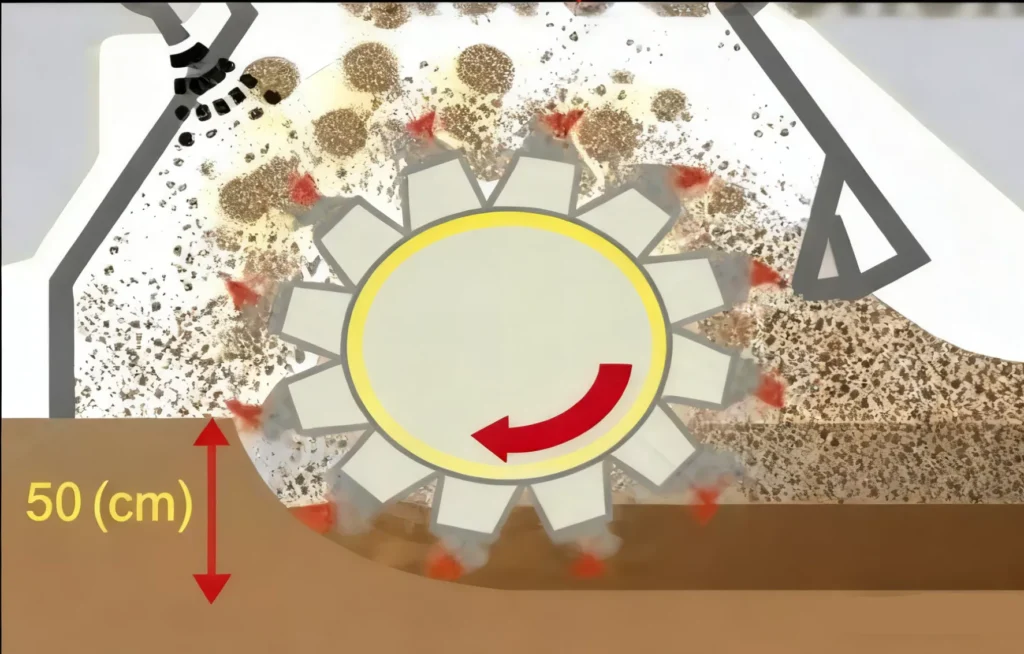

The Soil Stabilizer is the ultimate solution for high-performance road and ground stabilization, engineered for tractors with 300–500 HP. Combining a robust fixed-rotor system with a deep-processing crushing chamber, it delivers exceptional mixing quality at depths up to 50 cm—even in the most challenging conditions, such as hard, stony terrain. Its protruding rotor design ensures efficient stabilization with minimal power consumption, while the heavy-duty frame and wear-resistant materials guarantee long-term reliability.

Versatile and powerful, the excels in both small-scale projects and large infrastructure applications—including highways, airport runways, and parking lots—making it the definitive choice for professionals who demand precision, durability, and productivity.

Standard Equipment

- Hydraulic rear Hood with anti-clogging system

- Interchangeable inner antiwear plates in Hardox*

- Enclosed machine body

- Inside lateral protection

- Protection chains

- Transmission with side gearbox

- Side gearbox with oil cooling system

- Gearbox with freewheelGearbox with oil cooling system

- PTO shaft

- Friction clutches

- Bolted-on rotor shafts (in forged steel)

- Dozing blade

|

|---|

| W style self aligning device between PTO drive shaft/gearbox |

|

| Automatic FCS system for optimal soil mixing and moisture management |

|

| Dozing blade with springs system to level and compact the crushed material, creating a uniform base |

Options Equipment

- Multiple tooth options

- Hydraulic top link

- W style self-aligning device between PTO drive shaft/gearbox

- Dozing blades with spring system

- Water spray system WSS High Flow

- FCS full control system

Model Specifications

| Watanabe-SS225 | Watanabe-SS250 | Watanabe-HPSS225 | Watanabe--HPSS250 | |

|---|---|---|---|---|

| Tractor (hp) | 300–400 | 300–400 | 400–500 | 400–500 |

| PTO (rpm) | 1000 | 1000 | 1000 | 1000 |

| Working width (mm) | 2320 | 2560 | 2320 | 2560 |

| Total width (mm) | 2750 | 2990 | 2750 | 2990 |

| Weight (kg) | 6300 | 6500 | 6550 | 6750 |

| Rotor diameter (mm) | 1085 | 1085 | 1085 | 1085 |

| Max working depth (mm) | 500 | 500 | 500 | 500 |

| No. teeth (type A/3 + STC/FP + STC/3/FP + F/3/SS) |

6+4+4+4 | 68+4+4+4 | 6+4+4+4 | 68+4+4+4 |

How a Tractor-Mounted Soil Stabilizer Repairs and Upgrades Roads

-

Attachment & Power Transfer

The soil stabilizer is mounted directly to a high-horsepower agricultural or industrial tractor (typically 300–500 HP) via a standard three-point hitch. Power is delivered through the tractor PTO (Power Take-Off) shaft, which drives the machine’s heavy-duty rotor system. Many advanced models feature a W-style self-aligning PTO drive shaft to maintain smooth power transmission even on uneven terrain—critical for preventing driveline damage during aggressive operation. - Deep Soil Pulverization

As the tractor moves forward, the rotating drum—equipped with replaceable carbide-tipped teeth—acts like a PTO rock crusher, breaking up compacted soil, old pavement, gravel, and even small rocks down to a depth of up to 50 cm (20 inches). This process, known as pulverization, creates a uniform, loose base material ready for stabilization. - Precision Additive Injection

Simultaneously, an integrated liquid injection system (often enhanced with an FCS Full Control System) sprays water, cement slurry, lime, or eco-friendly polymer binders into the mixing chamber. The system precisely meters the additive based on travel speed and soil conditions, ensuring optimal moisture content and chemical bonding—key to achieving maximum strength and dust suppression. - In-Chamber Mixing & Homogenization

Inside the enclosed crushing and mixing chamber, the pulverized material and stabilizing agent are thoroughly blended by the high-torque rotor. The fixed-rotor design ensures consistent mixing quality, even in challenging soils like clay, laterite, or stony subgrades. -

Grading & Initial Compaction

A rear-mounted spring-loaded dozing blade levels the treated material, creating a smooth, uniform surface ready for compaction. This blade automatically adjusts to ground contours, eliminating ridges and ensuring proper crown or camber for drainage. - Final Curing & Use

After light rolling with a padfoot or smooth-drum roller, the stabilized base cures over 3–7 days. The result? A dust-free, all-weather road that resists rutting, erosion, and seasonal degradation—ideal for farm lanes, mining haul roads, rural highways, and emergency access routes.

Application Scenarios Highway and National Road Subgrade Treatment

Highway and National Road Subgrade Treatment

- Applications: Subgrade stabilization and Full Depth Reclamation (FDR) of old asphalt/gravel layers before new or renovated roads.

- Advantages: 50cm deep crushing + uniform mixing meets the strength requirements of high-grade highway subgrades; FCS system precisely controls moisture content and additive ratios to ensure mixing quality; Enclosed body + wear-resistant Hardox plates allow for high-intensity continuous operation.

Airport Runway and Apron Construction/Maintenance

- Applications: Subgrade stabilization before compaction to prevent settlement and rutting.

- Advantages: High-rigidity frame and heavy-duty rotor can handle hard subgrades containing gravel; Direct entry into compaction after bulldozing improves construction efficiency; Suitable for large-area scenarios with high-standard flatness requirements.

Large Logistics Park & Industrial Plant Roads

- Applications: Low-cost hardening solution for internal heavy-duty transport roads.

- Advantages: Cost reduction of over 60% compared to concrete or asphalt; Water spray system (WSS High Flow) effectively suppresses dust and improves the working environment; Spring-loaded bulldozer blades automatically adapt to the terrain, creating a smooth driving surface.

Mining and Forestry Roads

- Purpose: Construction of temporary or semi-permanent heavy-duty access roads.

- Advantages: Wear-resistant design handles high-abrasion conditions (gravel, slag, tree roots, etc.); W-type PTO automatic centering device adapts to inclined operations on rugged terrain; Can use various stabilizers such as lime, cement, or environmentally friendly polymers, flexibly adapting to different soil types.

Rural Roads and Rural Revitalization Projects

- Purpose: Ensuring smooth passage through villages during the rainy season.

- Advantages: Utilizes existing high-horsepower tractors (300–500 HP), eliminating the need for additional specialized equipment; Completes crushing, mixing, and initial leveling in one operation, resulting in fast construction speed; Significantly reduces dust and mud, improving the quality of life for residents.

Post-Disaster Emergency Road Repair

- Purpose: To rapidly restore vital transportation routes after earthquakes and floods.

- Advantages: Modular design facilitates transport to disaster areas; Locally sourced materials (original soil + a small amount of stabilizer) allow for rapid reconstruction of traffic capacity; High reliability ensures continuous operation under harsh conditions.

Client Cases 🌍 Customer Case 1: Highway Base RehabilitationName: Markus Weber Germany March 2024

🌍 Customer Case 1: Highway Base RehabilitationName: Markus Weber Germany March 2024

Application: Full-depth reclamation (FDR) of a service road alongside the A9 Autobahn, recycling old asphalt and subgrade to a depth of 45 cm.

“After evaluating three machines, we chose the STAB/FPS for its unmatched stability at high operating speeds. The fixed-rotor design handled continuous operation without vibration issues, and the FCS system gave us precise control over cement dosage—resulting in exceptional mixing homogeneity. We completed 1.8 km per day, cutting two weeks off the schedule. In Germany, where engineering tolerances are strict, this machine delivered exactly what we needed.”

🌾 Customer Case 2: Farm Logistics Road UpgradeSarah Thompson Australia November 2023

Application: Upgrading internal access roads across a 12,000-hectare wheat farm in New South Wales to ensure year-round heavy vehicle access.

“During the wet season, our trucks were stuck for days—costing us thousands. We mounted the STAB/FPS on our John Deere 8730 (420 HP) and stabilized 22 km of roads using locally sourced lime. Now, even after heavy rain, transport runs smoothly. The spring-mounted dozing blade created a surprisingly smooth surface—contractors thought we’d laid gravel! The ROI was achieved in under 12 months.”

⛏️ Customer Case 3: Mining Haul Road ConstructionCarlos Mendoza Chile July 2024

Application: Building durable haul roads in a copper mine in the Atacama Desert, where ground conditions include hard volcanic rock and extreme temperatures.

“The desert ground here is like concrete, littered with sharp basalt fragments. Most machines fail within days—but the STAB/FPS thrived. Its Hardox® wear plates and forged rotor shafts stood up to relentless abrasion. With the WSS High Flow spray system and polymer stabilizer, we cut dust by 80% and extended road life from 3 months to over 2 years. Even at 50°C, the oil-cooled gearbox never overheated. It’s now the talk of Chilean mining circles.”

🛣️ Customer Case 4: Rural Connectivity Project Dr. Amina Nkosi Kenya January 2024

Application: Government-funded rural road improvement program connecting 12 remote villages in Kenya’s Rift Valley Province

“Our budget was tight, but quality couldn’t be compromised. The STAB/FPS worked perfectly with our existing Case IH Magnum 340 tractor (340 HP)—no need for new capital investment. Local technicians were trained in just three days. Most impressively, it pulverized the tough laterite-and-basalt mix to full 50 cm depth, breaking through the hardpan layer that caused seasonal isolation. Now, children can reach school safely in the rainy season. This machine isn’t just equipment—it’s a lifeline.”

Why Professionals Choose Us

✅ Deep Technical Expertise

- Our engineering team includes civil engineers, soil mechanics specialists, and heavy machinery designers with decades of combined experience in road construction and ground improvement.

- We collaborate with leading universities (including TU Munich and Politecnico di Milano) on material science research to optimize stabilizer performance across diverse soil types.

✅ Field-Proven Innovation

- The STAB/FPS series was developed in direct response to contractor feedback: “We need one machine that can handle highways and village tracks.”

- Features like the FCS Full Control System, W-style PTO self-aligning device, and 50 cm deep-crushing chamber weren’t invented in a lab—they were refined on job sites where failure isn’t an option.

✅ Global Presence, Local Support

- Active in 42 countries with certified dealers and service partners in North America, Europe, Africa, Asia, and Latin America.

- 24/7 technical support in 8 languages, plus on-site training programs for operators and maintenance crews.

- Over 1,200 units deployed worldwide—with a 96% customer retention rate.

✅ Commitment to Quality & Sustainability

- All critical components (rotor shafts, gearbox housings, wear plates) are made from high-grade forged steel and Hardox® abrasion-resistant steel, sourced from certified EU suppliers.

- Our machines reduce the need for imported aggregates and asphalt—cutting CO₂ emissions by up to 70% compared to traditional paving.

- We offer compatibility with eco-friendly stabilizers, including bio-polymers and recycled binders.

🏆 Recognized Excellence

- Winner, Bauma Innovation Award 2022 – Ground Preparation Category

- Featured in “World Highways” Magazine (2023): “Redefining Rural Road Economics”

- Preferred Supplier for UNOPS rural infrastructure projects in East Africa

- Certified Partner of John Deere, Case IH, and New Holland for integrated tractor-implement solutions

💬 Our Promise to You

“We don’t just sell machines—we deliver lasting road performance. If your STAB/FPS doesn’t outperform expectations within the first 100 operating hours, we’ll work with you until it does.”

Additional information

| Editor | Miya |

|---|