About Us

For over 54 years, Watanabe has been at the forefront of designing and manufacturing high-performance, tractor-, excavator-, skid steer–, and special-vehicle-mounted attachments for forestry, agriculture, road construction, and humanitarian demining operations.

A Legacy of Innovation Since 1970

For over 54 years, the Watanabe name has stood for reliability, ingenuity, and unwavering commitment to farmers and infrastructure builders worldwide. What began in 1970 as a small agricultural sprayer dealership in Castro-Pr, Brazil—founded by Mr. Hitoshi Watanabe—has evolved into a globally recognized manufacturer with a strong presence in China and export operations across 60+ countries.

Mr. Watanabe’s deep connection with local farmers led him to develop the WTP-200 Two-Line Potato Picker in 1973—a breakthrough that revolutionized tuber harvesting in South America. Its overwhelming success prompted the establishment of the Hitoshi Watanabe Agricultural Implements Factory in 1976. After his passing in 1983, his family carried forward his vision, officially founding Watanabe Máquinas Agrícolas Indústria e Comércio Ltda. in 1984.

By the early 2000s, Watanabe had diversified into cotton defoliators, sugarcane loaders, forestry mulchers, and soil preparation equipment. In 2009, the company restructured as Watanabe Industry and Machine Trade Ltd., laying the groundwork for international expansion.

In 2018, recognizing the growing demand for land reclamation solutions in rocky terrains, Watanabe established its Shandong manufacturing base in Yishui, China—giving birth to Shandong Watanabe PTO Rock Crusher Co., Ltd., specializing in two core product lines:

- Agricultural Rock Crushers for farmland clearing

- Soil Stabilizers for road base construction

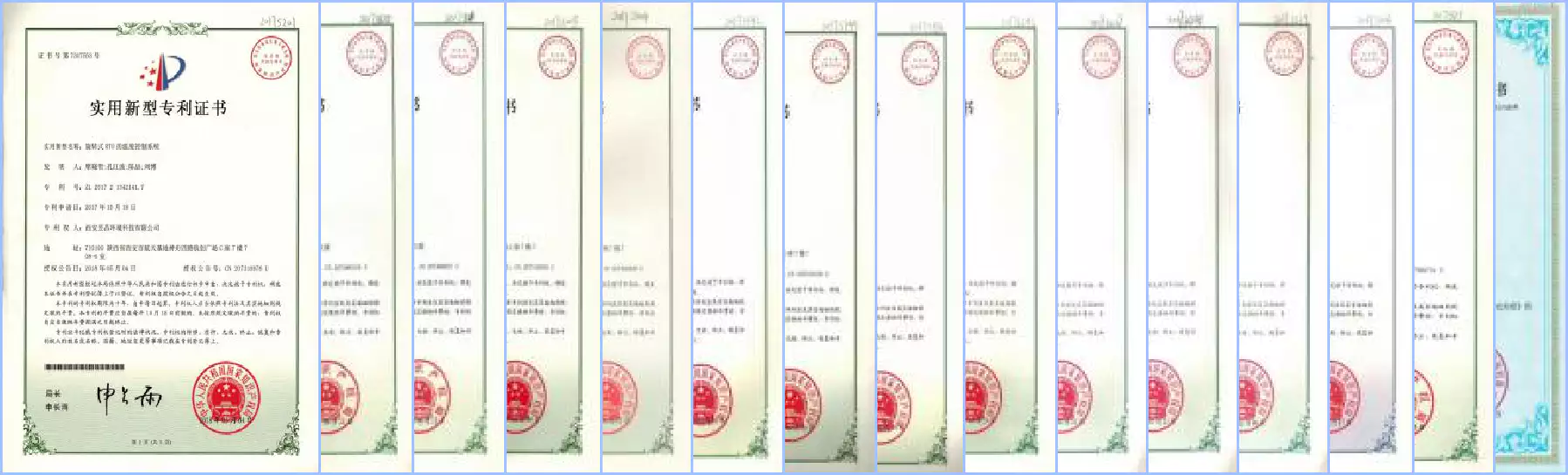

National Invention & Utility Model Patents

Smart Factory ㎡

Professionals

Core Product Lines

Rock Crushers / Stone Crushers

Designed for agricultural land reclamation and orchard development, these units efficiently crush surface and subsurface rocks up to 30 cm in diameter, turning barren, stony fields into arable land—without excavation or hauling.

Soil Stabilizers

Ideal for low-cost rural road construction and base stabilization, our soil stabilizers homogenize native soils while integrating lime, cement, or bitumen—achieving CBR improvements of 300–500% in a single pass.

Forestry & Land Clearing Attachments

- Forestry Mulchers

- Stump Grinders

- Land Clearing Rakes

Road Rehabilitation Equipment

- Cold Planers / Road Millers

- Reclaimers & Soil Mixers

- Multi-Function Carriages with Quick-Attach Systems

Advanced Production Equipments

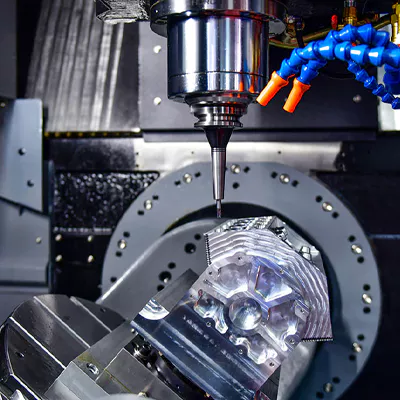

CNC Plasma & Fiber Laser Cutting Systems

Hydraulic Press Brakes

Robotic & Manual Welding Stations

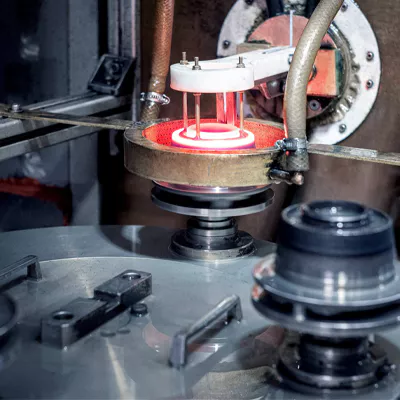

Induction Hardening & Shot Blasting

CNC Machining Centers

Automated Powder Coating Line

Quality Assurance You Can Trust

This isn’t just fabrication—it’s precision engineering for extreme durability. From the first cut of steel to the final field simulation, every Watanabe machines is built to outperform and outlast.

In-house Metallurgy Lab

Verifies steel grade (via spectrometer) and hardness (Rockwell tester)

Gearbox Endurance Testing

100-hour continuous run at max torque (up to 8,500 N·m)

Traceability System

Every machine has a QR code linking to its production log—material batch, weld records, test data

Certifications & Patents

We hold 15+ national patents, including:

- CN202310456789.1: “Modular Impact Rotor System for Multi-Grade Rock Crushing”

- CN202221122334.5: “Hydraulic Flow-Sensing Control for Soil Stabilizer Drum Speed Optimization”

All products meet international safety and quality benchmarks:

- ✅ CE Certified (Machinery Directive 2006/42/EC)

- ✅ ISO 9001:2015 Quality Management System

- ✅ GB/T 19001-2016 (China National Standard)

- ✅ SGS Verified Manufacturer since 2020

Our Service Process

From Inquiry to Long-Term Partnership

At Shandong Watanabe, we believe exceptional machinery deserves exceptional service. Our end-to-end support system ensures you get the right solution—fast, reliably, and with confidence.

Initial Consultation

You share your application: terrain type, tractor/excavator model, working width, material (rock size, soil condition), etc.

Our engineers provide a free feasibility assessment and recommend the optimal model

Customization & Quotation

We offer tailored configurations,

Detailed quotation with technical drawings, delivery timeline, and FOB/CIF terms within 24 hours.

Production Tracking

Upon order, you receive a production schedule with weekly photo/video updates.

All critical components are traceable via unique serial numbers.

Pre-Delivery Inspection (PDI)

Every machine undergoes 72-hour factory acceptance test (FAT) under real-load conditions.

Inspection report + operation manual provided before shipment.